In the competitive world of coffee production, achieving the perfect grind is crucial for maximizing flavor and aroma. The Industrial Coffee Grinder System is designed to meet the demands of large-scale coffee processing, offering advanced features that elevate your coffee quality and streamline production. In this article, we’ll explore the key benefits of this system and why it can help you outrank your competitors.

What is the Industrial Coffee Grinder System?

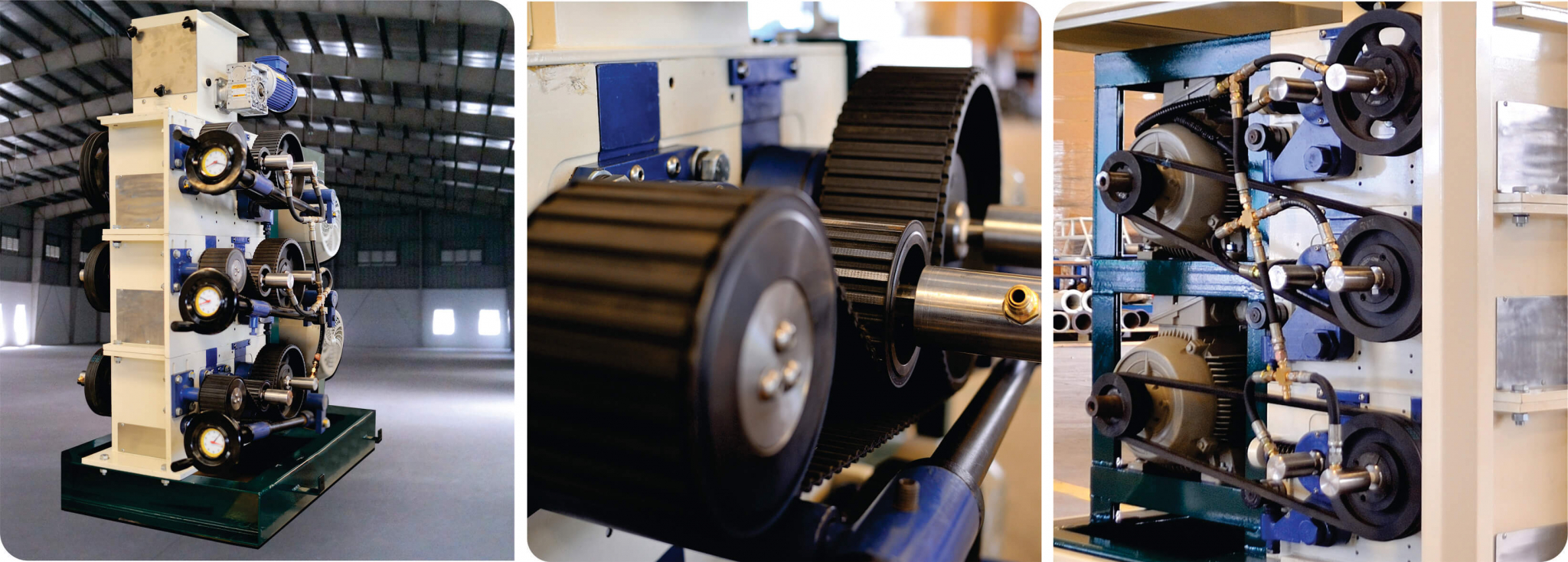

An Industrial Coffee Grinder is specialized equipment engineered for high-volume coffee grinding in commercial settings, such as coffee processing plants. These grinders are capable of rapidly processing large quantities of coffee beans, making them suitable for various brewing methods, including espresso, filter coffee, and pod/capsule systems.

The VNT's Industrial Coffee Grinder System stands out by offering multiple grind settings tailored to specific brewing techniques. This versatility ensures that you achieve the ideal particle size for each method, unlocking the full potential of your coffee beans and resulting in a richer, more enjoyable coffee experience.

Key Benefits of the Industrial Coffee Grinder System

1. Versatile Grind Settings

One of the standout features of the Industrial Coffee Grinder System is its multiple grind settings. Whether you need a fine grind for espresso or a coarser grind for French press, this system allows you to customize the grind size to match various brewing methods. This flexibility is essential for meeting diverse customer preferences and ensuring that each cup of coffee is brewed to industrial coffee grinder machine perfection.

2. Consistent Grind Quality

Consistency is key in coffee production, as even slight variations in grind size can significantly impact flavor. The Industrial Coffee Grinder System produces uniform grinds, minimizing inconsistencies that can lead to uneven extraction. By ensuring that every batch of ground coffee is consistent, you enhance the overall flavor profile, resulting in a superior product that keeps customers coming back for more.

3. Temperature Control for Freshness

Coffee beans contain volatile aromatic oils that contribute to their unique flavors and aromas. The Industrial Coffee Grinder System incorporates temperature control during the grinding process, preserving these essential oils and preventing them from degrading. By maintaining optimal temperatures, you ensure that your ground coffee retains its freshness, delivering a rich and aromatic experience to your customers.

Technical Specifications

Here’s a closer look at the technical features of the Industrial Coffee Grinder System:

Product Functions

Grinding Post-Roasting: Specifically designed for grinding coffee after roasting.

Multiple Grinding Types: Capable of handling various grind sizes for different brewing methods.

Temperature Control: Maintains optimal conditions during grinding to preserve flavor.

Product Advantages

Automatic Machine Cleaning: Reduces downtime and maintenance efforts.

High Durability: Built to withstand the rigors of daily use in high-volume settings.

User-Friendly Operation: Easy to operate, making it accessible for staff at all skill levels.

Energy Efficiency: Designed to save energy while delivering high performance.

Why Choose VNT's Industrial Coffee Grinder System?

With over 30 years of experience in manufacturing equipment for processing agricultural products, including coffee, VNT understands the unique challenges faced by coffee producers. We offer tailored advice based on your specific capacity requirements and factory location, ensuring you get the best solution for your business.

If you're looking to enhance your coffee production and deliver exceptional quality to your customers, the Industrial Coffee Grinder System is your key to success.

For more information or to schedule a visit, please contact our hotline at 0966 757 757. Elevate your coffee grinding process and stay ahead of the competition today!